Castle Group has been committed to building sustainable partnerships and delivering quality construction services for twenty-five years. In 2018, we expanded our expertise by establishing Castle Modular, a pivotal division specialising in high-quality modular solutions using advanced off-site manufacturing processes.

Benefits of Castle Modular Construction

The Castle Group Difference

At Castle Modular, we deliver innovative, high-quality modular solutions that combine speed, flexibility, and precision. Our approach ensures faster project delivery without compromising on safety or standards.

From design through to installation and final turnover, our specialist team manages every stage of the process. With a focus on efficiency and collaboration, Castle Modular provides clients with a seamless, end-to-end service tailored to their specific needs.

Schedule Benefits

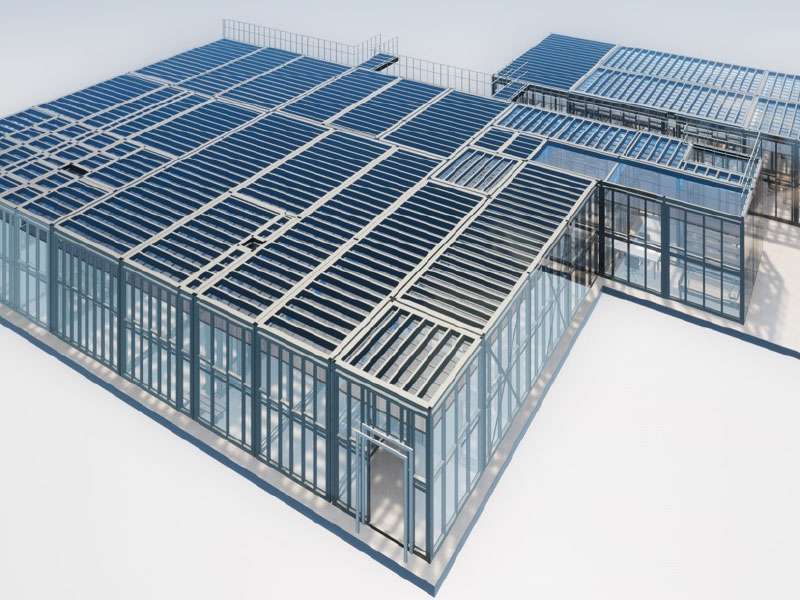

Utilising Castles volumetric 3D solutions result in schedule benefits of up to 50% for critical infrastructure or complete volumetric buildings.

Efficiency

Allows for simultaneous site preparation and factory-based construction.

Standardisation

A controlled manufacturing environment leads to higher precision and quality control, reducing defects and rework.

Carbon & Sustainability

Full carbon tracking and a clear plan to reduce environmental impact on every project.

Quality Assured

EN1090 and ISO 9001 certification ensure our commitment to high-quality standards.

Safety Assured

ISO 45001 certification underscores our focus on maintaining safe construction practices

Environmentally Assured

ISO 14001 certification highlights our dedication to environmental management and sustainability.

Design Led

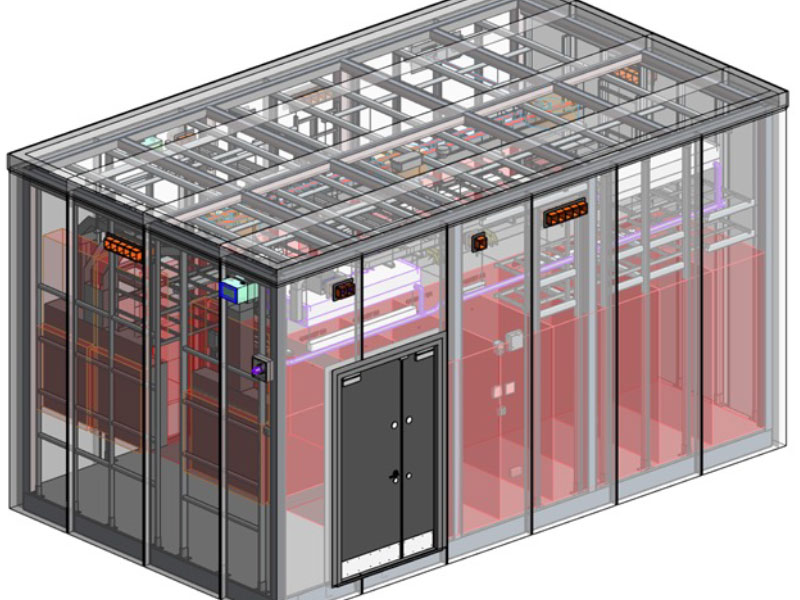

At Castle Modular, we design with precision before we build. Our in-house 3D BIM capability, up to Level of Design (LOD) 500, ensures that all potential clashes and coordination issues are resolved before manufacturing begins.

We utilise Revit and other federated modelling platforms for seamless integration and clash detection, giving clients total confidence in the final design.

On the factory floor, the latest touchscreen technology keeps our skilled teams working with the most up-to-date models – ensuring accuracy, efficiency, and certainty at every stage.

Building Code Compliance

Our engineers utilise our extensive suite of in-house test data to ensure the fire, structural, acoustics and thermal requirements of every project are considered and designed for from the initial design concept stage.

Where necessary, we carry out bespoke tests to ensure compliance with European and local building codes. Tests can be carried out for bespoke designs where required. Our experienced Test Teams work with our partners (clients and supply chain) to ensure that people and product safety is at the forefront of all our designs.

Design Led

At Castle Modular, we design with precision before we build. Our in-house 3D BIM capability, up to Level of Design (LOD) 500, ensures that all potential clashes and coordination issues are resolved before manufacturing begins.

We utilise Revit and other federated modelling platforms for seamless integration and clash detection, giving clients total confidence in the final design.

On the factory floor, the latest touchscreen technology keeps our skilled teams working with the most up-to-date models — ensuring accuracy, efficiency, and certainty at every stage.

Building Code Compliance

Our engineers utilise our extensive suite of in-house test data to ensure the fire, structural, acoustics and thermal requirements of every project are considered and designed for from the initial design concept stage.

Where necessary, we carry out bespoke tests to ensure compliance with European and local building codes. Tests can be carried out for bespoke designs where required. Our experienced Test Teams work with our partners (clients and supply chain) to ensure that people and product safety is at the forefront of all our designs.

MODULAR SOLUTIONS

Castle Modular delivers a comprehensive range of Electrical, Data, Healthcare, Life Science, and Specialist Modules, each designed to provide a secure, high-performance environment for critical equipment and facilities.

Our modules are suitable for installation indoors or outdoors, onshore or offshore, and are:

TER Rooms

Telecommunications Equipment Rooms designed for critical data infrastructure. Engineered for security, resilience, and seamless integration into data centre environments.

EPods

Pre-fabricated Electrical Pods: housing switchgear, transformers, and associated equipment. Delivered fully tested and ready for rapid installation, reducing on-site time and risk.

UPS Modules

Purpose-built modular units housing UPS systems, ensuring secure and resilient backup power for critical infrastructure.

Security Guard Houses

Modular guard houses designed for 24/7 site security. Fully customisable with access control, CCTV integration, and climate-controlled environments.

Modular Admin Buildings

Flexible, high-quality office and welfare facilities delivered as standalone or multi-storey solutions. Built to support operations across industrial, commercial, and infrastructure sites.

Modular Cleanrooms

Specialist modular cleanroom facilities for pharma, biotech, and life sciences. Delivered to ISO standards with integrated HVAC, filtration, and environmental controls.

Multistorey Modular Buildings

Scalable solutions for commercial, residential, and healthcare facilities, designed for speed and efficiency.